Thinking how to Properly Store Vacuum Packed BBQ? Storing vacuum packed products correctly and turning them to healthy meals prepared to eat is essential to maintain their quality, safety, and flavour. Proper storage techniques can extend the shelf life of these products, prevent spoilage, and ensure they remain delicious and safe to eat. This comprehensive guide covers everything from the basics of vacuum packing to advanced storage tips.

Understanding Vacuum Packing

Vacuum packing is a method of packaging that removes air from the package before sealing it. This process involves placing the food in a plastic film package, removing air from inside, and sealing the package. The vacuum-sealed environment helps preserve the food by reducing atmospheric oxygen, limiting the growth of aerobic bacteria or fungi, and preventing the evaporation of volatile components.

Extended Shelf Life

The primary benefit of vacuum packing is the significant extension of shelf life. By removing air, the growth of spoilage organisms like mould and bacteria is greatly reduced. For BBQ products, which often have marinades or spices, vacuum packing helps maintain the integrity of these flavours over time. For instance, vacuum-sealed smoked meats can retain their quality for weeks compared to just a few days when stored conventionally.

Protection from External Elements

Vacuum packing also provides excellent protection from external elements such as moisture and contaminants. This is particularly important for BBQ products that are stored in environments prone to temperature fluctuations or humidity, such as outdoor events or busy kitchens. The vacuum-sealed barrier ensures that the products are shielded from these potentially damaging conditions.

Preservation of Flavour and Nutrients

Flavour preservation is another significant advantage. BBQ products, which often undergo extensive seasoning and marinating processes, can lose their distinctive tastes if exposed to air. Vacuum packing locks in the flavours and prevents the loss of aromatic compounds. Additionally, nutrients, especially delicate ones like certain vitamins, are better preserved in a vacuum-sealed environment, ensuring the BBQ products are not only tasty but also nutritious.

Preparing BBQ Products for Vacuum Packing

Before vacuum packing BBQ products, it’s essential to prepare them correctly to ensure maximum freshness and longevity.

Cooling Down Properly

Ensuring BBQ products are cooled down to room temperature before vacuum packing is crucial. Packing hot or warm items can create condensation inside the package, leading to bacterial growth. Rapid cooling methods, such as placing the BBQ products in shallow containers and refrigerating them promptly, can help speed up this process. Using an ice bath for faster cooling is also effective, especially for larger cuts of meat or bulk quantities.

Cleaning and Drying

Cleanliness is paramount when preparing BBQ products for vacuum packing. Ensuring that all surfaces, utensils, and hands are clean reduces the risk of contamination. BBQ products should be patted dry with paper towels to remove any excess moisture, which can interfere with the vacuum sealing process and promote bacterial growth. For items like ribs or chicken wings, trimming excess fat can also help achieve a cleaner seal.

Pre-Freezing if Necessary

For very moist items, pre-freezing them slightly before vacuum packing is beneficial. This step helps in achieving a better seal by solidifying any liquid that might otherwise interfere with the sealing process. Place the BBQ products on a baking sheet lined with parchment paper and freeze them for about 30 minutes to an hour. This slight freezing makes them easier to handle and ensures a tighter vacuum seal.

Choosing the Right Vacuum Sealer and Bags

Selecting the appropriate vacuum sealer and bags is crucial for effective storage. There are various types of vacuum sealers available, ranging from basic models to more advanced ones with multiple settings.

Types of Vacuum Sealers

External Vacuum Sealers: These are suitable for home use and small quantities. They are relatively inexpensive and easy to use, making them a popular choice for households. External vacuum sealers work by clamping the bag’s open end and removing the air before sealing it. They are best suited for solid and semi-solid foods.

Chamber Vacuum Sealers: These are ideal for commercial use, handling larger volumes and liquid-rich foods better. Unlike external sealers, chamber vacuum sealers place the entire bag inside the machine, where both air removal and sealing occur. This method is highly effective for liquid-rich foods and provides a more robust and consistent seal.

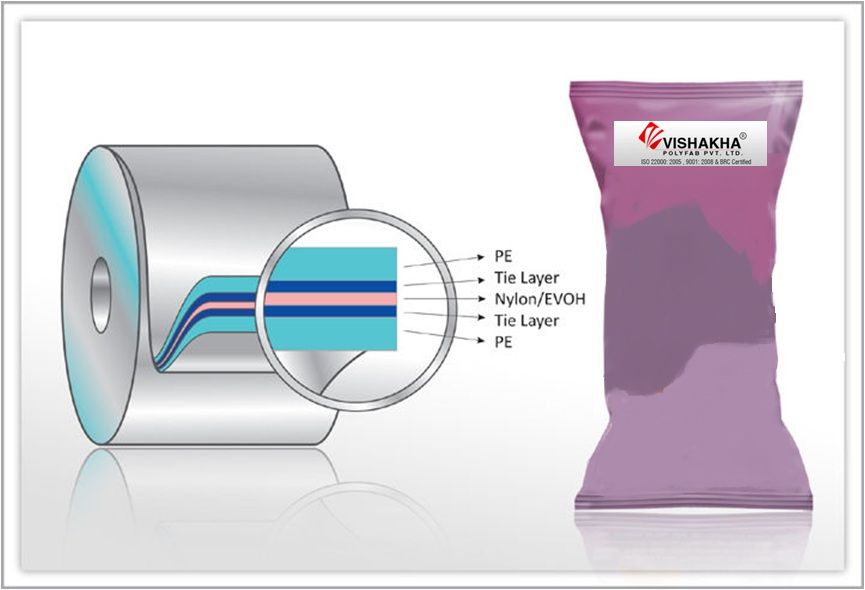

Vacuum Bags

Choosing high-quality, multi-layer bags that are puncture-resistant is essential for maintaining the integrity of the vacuum seal. Look for bags that are designed specifically for vacuum sealing, as they are usually made from durable materials that can withstand freezing and boiling. Some vacuum bags come with built-in zippers, allowing for easy resealing after the initial opening, which is convenient for items that are used frequently.

Ideal Storage Conditions

Storing vacuum packed BBQ products under optimal conditions is key to maintaining their quality.

Refrigeration

Temperature: Store vacuum packed BBQ products at a consistent temperature of 1-4°C (34-39°F). This range is optimal for inhibiting bacterial growth and ensuring the products remain fresh.

Duration: Generally, vacuum-sealed BBQ products can be refrigerated for up to 2 weeks. However, the exact duration can vary depending on the type of product and its initial freshness.

Freezing

Temperature: Keep at -18°C (0°F) or lower. This temperature is ideal for preserving the quality and safety of vacuum-sealed BBQ products over long periods.

Duration: Vacuum-sealed BBQ products can be stored in the freezer for up to 2 years without significant loss of quality. However, for best taste and texture, it is advisable to use them within 1 year.

Avoiding Common Storage Mistakes

Proper storage involves avoiding common pitfalls that can compromise the quality of vacuum packed BBQ products.

Fluctuating Temperatures

Frequent temperature changes can cause condensation inside the bag, leading to bacterial growth and spoilage. To prevent this, store vacuum-sealed BBQ products in a dedicated area of the refrigerator or freezer where the temperature remains stable. Avoid placing them near the door or in areas prone to temperature variations.

Overpacking

Do not overfill the vacuum bags, as it can lead to inadequate sealing. Leave enough space at the top of the bag to ensure a proper seal. Overpacking can also cause the bags to burst, leading to exposure to air and contaminants.

Improper Sealing

Ensure that the bags are sealed properly. A faulty seal can let air in, leading to spoilage. Double-check the seal after the vacuuming process and look for any signs of air inside the bag. If the seal appears weak, consider resealing the bag or using a new one.

Labelling and Organisation

Keeping track of vacuum packed BBQ products is easier with proper labelling and organisation.

Labelling Tips

Date of Packaging: Always include the date when the product was vacuum packed. This helps in tracking the freshness and knowing when to use the product.

Contents and Quantity: Clearly label the type of BBQ product and its quantity. This is especially useful for bulk storage and ensures you use the right amount for your needs.

Organisation Strategies

FIFO System: Follow the “First In, First Out” method to ensure older items are used first. This helps in preventing wastage and ensures that all products are used within their optimal time frame.

Categorisation: Store similar items together to make retrieval easier. For example, keep all marinated meats in one section and all smoked products in another. This organisation helps in quickly locating items and maintaining a tidy storage area.

Thawing Vacuum Packed BBQ Products

Thawing vacuum packed BBQ products correctly is as important as the storage process.

Thawing Methods

Refrigerator Thawing: The safest method, allowing the product to thaw gradually in the fridge. Place the vacuum-sealed bag on a plate or in a container to catch any possible drips. This method takes longer but ensures even thawing and minimises the risk of bacterial growth.

Cold Water Thawing: Place the vacuum-sealed bag in cold water. Change the water every 30 minutes to ensure safe thawing. This method is faster than refrigerator thawing and is useful for smaller cuts of meat. Ensure the bag remains sealed to prevent water from entering and contaminating the product.

Microwave Thawing: Use if necessary, but be cautious of uneven heating. This method is the quickest but can lead to partial cooking of the meat, affecting texture and taste. Use the microwave’s defrost setting and check the product frequently to avoid over-thawing.

Safety and Hygiene Practices

Maintaining high standards of safety and hygiene is critical when handling vacuum packed BBQ products.

Safety Tips

Hand Washing: Always wash hands before handling vacuum packed products. Use warm water and soap, scrubbing for at least 20 seconds to remove any potential contaminants.

Clean Surfaces: Ensure all surfaces and utensils are clean and sanitised. Use food-safe sanitising solutions to wipe down counters, cutting boards, and knives. This helps in preventing cross-contamination and maintaining food safety.

Avoid Cross-Contamination: Keep raw and cooked products separate. Use different utensils and cutting boards for raw meats and ready-to-eat foods. Store raw products on lower shelves in the fridge to prevent drips from contaminating other items.

Can I vacuum pack BBQ sauces and marinades?

Yes, you can vacuum pack BBQ sauces and marinades, but it requires a careful approach to avoid spills and ensure a proper seal. Using a chamber vacuum sealer is highly recommended for liquid-rich items like sauces and marinades. This type of sealer places the entire bag inside a chamber, where the air is removed from the chamber and the bag simultaneously. This method prevents the liquid from being sucked out of the bag and ensures a clean and effective seal. If you are using an external vacuum sealer, consider pre-freezing the sauce or marinade slightly before sealing to reduce the risk of spills.

How do I know if a vacuum-sealed bag has lost its seal?

There are several signs that a vacuum-sealed bag may have lost its seal:

- Air inside the bag: If you notice air pockets or bubbles inside the bag, this indicates that the seal has been compromised.

- Loose seal: The bag should be tight around the contents. If the bag appears loose or puffy, it means air has entered.

- Visible leaks: Any visible leaks or tears in the bag suggest that the seal is not intact.

If you suspect that a vacuum-sealed bag has lost its seal, it’s best to repack the product. To do this, inspect the bag for any damage, replace it if necessary, and use the vacuum sealer to create a new seal. It’s important to regularly check vacuum-sealed products to ensure they remain properly sealed and safe for consumption.

Can I reuse vacuum bags?

Reusing vacuum bags is not recommended, especially for storing raw meats or BBQ products, due to the risk of contamination. The process of vacuum sealing can cause microscopic punctures and wear in the bags, compromising their integrity over repeated use. Moreover, bacteria and other pathogens from the original contents can remain in the bag even after washing, posing a risk of cross-contamination.

For non-perishable items like nuts or dried fruits, reusing bags might be acceptable if they are thoroughly cleaned and sanitized. However, for BBQ products, it is best to use new bags each time to ensure food safety and maintain the quality of the stored items.

What should I do if my vacuum sealer isn’t working properly?

If your vacuum sealer isn’t working properly, follow these troubleshooting steps:

- Check the power source: Ensure that the sealer is plugged in and switched on.

- Inspect the sealing strip: The sealing strip should be clean and free of any debris. Wipe it down with a damp cloth if necessary.

- Test the bag placement: Make sure the open end of the bag is correctly placed inside the vacuum sealer.

- Check for bag damage: Inspect the vacuum bags for any tears or punctures that might be affecting the seal.

- Consult the manual: Refer to the user manual for specific troubleshooting advice and contact customer support if needed.

Maintaining your vacuum sealer by regularly cleaning it and following the manufacturer’s guidelines can help prevent issues and ensure it operates efficiently.

Are there specific BBQ products that shouldn’t be vacuum packed?

While most BBQ products can be vacuum packed effectively, there are a few exceptions:

- Freshly cooked hot items: These should not be vacuum packed immediately. Allow them to cool to room temperature first to avoid condensation inside the bag.

- Very soft or delicate items: Products like soft cheeses or delicate baked goods might get crushed under the pressure of vacuum packing.

- Fermenting products: Items that continue to ferment, like certain types of cured meats or cheeses, can produce gases that may break the vacuum seal.

For these items, consider alternative storage methods or take extra precautions to ensure they are properly prepared for vacuum packing.

References

- Food Safety Authority of Ireland. (2023). Vacuum Packing Food: Advice and Guidance.

- USDA Food Safety and Inspection Service. (2023). Safe Food Handling.

- National Center for Home Food Preservation. (2023). Preserving Food: Freezing and Vacuum Packaging.

- Harvard Health Publishing. (2023). Food Storage Guidelines: How Long Can You Keep It?

- University of Minnesota Extension. (2023). Safe Home Food Storage.