Cryovac packaging, a form of vacuum packaging, has become a cornerstone of the food industry, particularly Budget-Friendly Ready-to-Eat Meals and in our BBQ catering. This innovative method extends the shelf life of BBQ products while preserving their flavour, texture, and nutritional value. By understanding the science behind Cryovac-packed BBQ products, caterers can optimise their processes and deliver superior quality food to their clients. The advent of Cryovac packaging has not only revolutionised food storage but also transformed the logistics of BBQ catering, enabling caterers to plan and execute large events with greater efficiency and reliability.

In BBQ catering in gold coast, where freshness and quality are paramount, Cryovac packaging offers a reliable solution to common challenges such as spoilage and food safety. The ability to store BBQ meats and other perishable items for extended periods without compromising their quality means that caterers can prepare well in advance, reducing last-minute rushes and ensuring consistent product quality. This introduction to Cryovac packaging sets the stage for a deeper exploration of its mechanisms, benefits, and applications in the BBQ catering industry.

The Basics of Cryovac Packaging

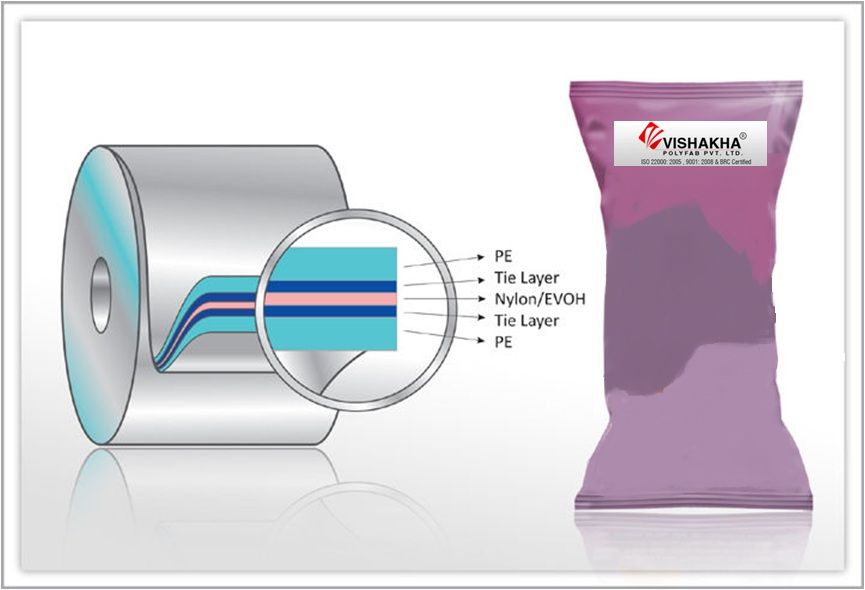

Cryovac packaging involves removing air from the packaging before sealing it, creating a vacuum environment. This process significantly slows down the growth of aerobic bacteria and fungi, which require oxygen to thrive. By creating an anaerobic environment, Cryovac packaging ensures that BBQ meats and other perishable items remain fresh for longer periods. The packaging material used in Cryovac is typically a multi-layered film that provides an excellent barrier against moisture and oxygen, further enhancing the preservation effect.

The removal of air from the packaging prevents oxidative reactions that can lead to spoilage and degradation of food quality. In the context of BBQ meats, this means that the colour, flavour, and texture of the meat are preserved for a longer time. Additionally, the vacuum environment helps in retaining the natural juices and tenderness of the meat, which are crucial for delivering a high-quality BBQ experience. The technology behind Cryovac packaging has evolved over the years, with modern equipment offering more efficient and reliable sealing, making it accessible to both large-scale caterers and small BBQ businesses.

Table: Oxygen Reduction in Cryovac Packaging

| Packaging Type | Oxygen Level (%) | Shelf Life Increase |

|---|---|---|

| Standard Wrap | 21 | Baseline |

| Cryovac | 0.5 – 1 | 2-3 times longer |

Preservation Mechanism

The primary mechanism behind the preservation effect of Cryovac packaging is the reduction of oxygen levels. Oxygen is a key factor in the spoilage of food as it supports the growth of spoilage microorganisms and oxidative reactions that degrade food quality. By vacuum sealing BBQ products, the oxygen level inside the package is reduced to a minimum, thus preventing these spoilage mechanisms. This is particularly beneficial for BBQ meats, which are prone to spoilage due to their high moisture and protein content.

The vacuum sealing process also inhibits the growth of aerobic bacteria, which require oxygen to survive and multiply. Without oxygen, these bacteria cannot grow, thereby extending the shelf life of the packaged food. Furthermore, the multi-layered film used in Cryovac packaging acts as a barrier against external contaminants and environmental factors that can lead to spoilage. This comprehensive protection ensures that the BBQ products remain fresh and safe for consumption for an extended period.

In addition to inhibiting microbial growth, Cryovac packaging helps in retaining the sensory qualities of the food. The absence of oxygen prevents the oxidation of fats, which can lead to rancidity and off-flavours. As a result, the BBQ meats maintain their original flavour and aroma, providing a superior dining experience. The preservation mechanism of Cryovac packaging is a combination of physical and chemical processes that work together to keep the food fresh and nutritious.

Table: Microbial Growth Inhibition in Cryovac Packaging

| Microorganism Type | Growth Requirement | Inhibition in Cryovac |

|---|---|---|

| Aerobic Bacteria | Oxygen | Yes |

| Anaerobic Bacteria | No Oxygen | No (proper storage needed) |

Benefits for Prepared BBQ Meals

Cryovac packaging offers several benefits for BBQ products, making it an invaluable tool for caterers. The most significant advantage is the extended shelf life, which allows BBQ meats to be stored for weeks instead of days without compromising quality. This extended storage capability means that caterers can prepare large quantities of food in advance, reducing the pressure of last-minute preparations and ensuring that they can meet high demand during peak times.

Enhanced flavour is another critical benefit. The absence of oxygen in the packaging prevents oxidative reactions that can cause off-flavours in the meat. This preservation of natural flavours ensures that the BBQ products taste fresh and delicious, even after extended storage periods. Additionally, the vacuum-sealed environment helps retain the moisture and tenderness of the meats, which are essential qualities for high-quality BBQ. The meats remain juicy and tender, providing a superior dining experience for customers.

Nutritional preservation is also a significant advantage of Cryovac packaging. Essential nutrients, such as proteins and vitamins, are better preserved in a vacuum-sealed environment. This means that the BBQ products not only taste better but are also more nutritious, offering greater value to customers. The ability to maintain the nutritional integrity of the food is particularly important for caterers who prioritise health and wellness in their offerings.

List: Benefits of Vac Packaging for BBQ Products

- Extended shelf life

- Enhanced flavour retention

- Improved texture and juiciness

- Nutritional preservation

- Reduced food waste

- Consistent product quality

Impact on BBQ Catering

For BBQ caterers, the benefits of Cryovac packaging are manifold. It allows for better inventory management, as products can be prepared in advance and stored without fear of rapid spoilage. This is particularly advantageous for large events where the demand for BBQ meats can be high. The ability to store pre-prepared meats means that caterers can focus on the cooking and serving aspects during the event, ensuring a smooth and efficient operation.

The consistent quality ensured by Cryovac packaging can enhance customer satisfaction and reduce food waste. Customers receive high-quality, fresh-tasting BBQ products, which can lead to repeat business and positive word-of-mouth. Furthermore, the extended shelf life reduces the risk of food spoilage, thereby minimising waste and increasing profitability. For caterers, this means more efficient use of resources and better financial performance.

Example: Inventory Management for Large BBQ Events

| Event Type | Number of Guests | Meat Required (kg) | Preparation Time | Shelf Life (Cryovac) |

|---|---|---|---|---|

| Small Gathering | 50 | 25 | 1 day | 2-3 weeks |

| Large Festival | 500 | 250 | 3 days | 2-3 weeks |

Cryovac packaging also offers logistical benefits. The compact and efficient packaging reduces storage space requirements, making it easier to transport and store large quantities of food. This is particularly beneficial for caterers who operate in limited space environments or need to transport food over long distances. The durability and reliability of Cryovac packaging ensure that the food remains in optimal condition throughout the supply chain, from preparation to serving.

Technical Aspects of Cryovac Packaging

Cryovac packaging requires specialised equipment, including vacuum sealers and packaging materials. The vacuum sealer removes air from the package and seals it tightly, creating the anaerobic environment necessary for preservation. The packaging materials, typically multi-layer films, are designed to provide a strong barrier against oxygen and moisture, further enhancing the preservation effect.

Advances in Cryovac technology have led to the development of more efficient and reliable sealing machines. Modern vacuum sealers are equipped with features such as adjustable vacuum levels, sealing times, and automatic operation, making the process more efficient and user-friendly. These advancements have made Cryovac packaging accessible to a wider range of caterers, from large-scale operations to small BBQ businesses.

The packaging materials used in Cryovac are also crucial to its effectiveness. Multi-layer films are designed to provide a robust barrier against oxygen and moisture, ensuring that the vacuum environment is maintained throughout the storage period. These films are also puncture-resistant, providing additional protection against physical damage. The choice of packaging materials can significantly impact the overall effectiveness of Cryovac packaging, making it essential for caterers to select high-quality materials.

Food Safety Considerations

While Cryovac packaging greatly extends the shelf life of BBQ products, it is crucial to maintain proper food safety practices. Vacuum-sealed products should be stored at appropriate temperatures to prevent the growth of anaerobic bacteria, such as Clostridium botulinum, which can thrive in low-oxygen environments. Regular monitoring and adherence to food safety guidelines are essential to ensure the safety and quality of Cryovac-packed BBQ products.

Proper storage conditions are critical for the effectiveness of Cryovac packaging. The vacuum-sealed products should be stored at temperatures below 4°C (39°F) to inhibit the growth of harmful bacteria. Additionally, the products should be used within the recommended shelf life to ensure safety and quality. Regular inspection of the packaging for any signs of damage or leaks is also essential to maintain the integrity of the vacuum seal.

List: Food Safety Tips for Cryovac-Packed BBQ Products

- Store at temperatures below 4°C (39°F)

- Use within the recommended shelf life

- Regularly inspect packaging for damage or leaks

- Follow food safety guidelines and regulations

- Educate staff on proper handling and storage procedures

Environmental Impact

Cryovac packaging, like all plastic-based packaging, raises environmental concerns. However, advancements in biodegradable and recyclable packaging materials are mitigating some of these impacts. Caterers can adopt sustainable practices by choosing eco-friendly Cryovac materials and implementing recycling programs.

The environmental impact of Cryovac packaging can be significant due to the use of plastic materials. However, the industry is moving towards more sustainable solutions, such as biodegradable films made from renewable resources. These materials offer the same protective qualities as traditional plastic films but decompose more rapidly and have a lower environmental footprint. Caterers can contribute to sustainability by selecting these eco-friendly options, thus reducing their overall environmental impact.

Another approach to minimising the environmental impact of Cryovac packaging is through recycling programs. Properly recycling used packaging materials can significantly reduce waste and promote a circular economy. Caterers can implement recycling initiatives within their operations, educating staff and customers on the importance of proper disposal and recycling practices. By doing so, they not only reduce waste but also set an example for others in the industry to follow.

List: Sustainable Practices for Cryovac Packaging

- Use biodegradable Cryovac films

- Implement recycling programs for used packaging

- Educate staff and customers on proper disposal methods

- Opt for suppliers that prioritise sustainability

- Monitor and reduce packaging waste

Additionally, reducing packaging waste is a key aspect of sustainable Cryovac usage. Caterers can achieve this by optimising the packaging process to use the minimum necessary material while still ensuring product protection. This can involve using right-sized packaging and avoiding excessive use of film. Streamlining packaging operations not only reduces waste but also can lead to cost savings.

Conclusion

The science behind Cryovac-packed BBQ products offers significant benefits for BBQ caterers, including extended shelf life, enhanced flavour, and improved texture. By understanding and implementing Cryovac packaging, caterers can ensure the delivery of high-quality, safe, and delicious BBQ products to their clients, while also considering environmental sustainability. The technical and safety aspects of Cryovac packaging must be carefully managed to maximise its advantages, making it a valuable tool in the BBQ catering industry.

Cryovac packaging has revolutionised BBQ catering by providing a reliable method to preserve the freshness, flavour, and nutritional value of BBQ products. This innovative technology allows caterers to plan and prepare in advance, ensuring consistent quality and customer satisfaction. However, it is essential to balance these benefits with environmental responsibility, adopting sustainable practices to mitigate the impact of plastic packaging. By doing so, BBQ caterers can continue to delight their customers with high-quality products while contributing to a more sustainable future.